Nov 27, 2019 (LBO) – UNIDO, with the public sector, has granted hi-tech machinery for the production of bamboo boards from within Sri Lanka for the first time.

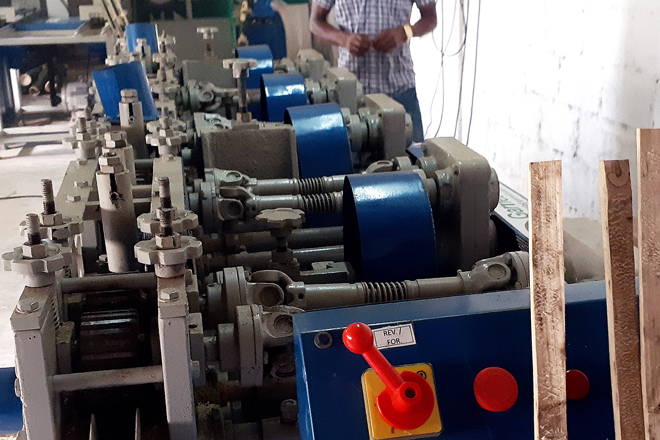

The first such hi-tech machinery series used for the production of bamboo boards to be set up in Sri Lanka greatly enhances creation of glue-laminated timber boards based on local bamboo supplies.

The latest breakthrough is a part of “Bamboo Processing Sri Lanka” -a project launched by the United Nations Industrial Development Organization (UNIDO), funded by Global Environment Facility (GEF) and is implemented in collaboration with the Ministry of Industries & Supply Management of Sri Lanka.

The objective of this project is to develop a bamboo supply chain and product industry in Sri Lanka.

Bamboo is an exceptionally fast-growing and resilient plant. Producing laminated boards from bamboo will reduce logging pressure on existing forests and therefore protect the environment.

Until now, glue-laminated bamboo boards had to be imported to Sri Lanka from neighbouring countries.

This machinery greatly enhances the creation of glue-laminated timber boards from bamboo within Sri Lanka for the first time, which can then be further processed with standard wood processing machinery into the full range of timber products, without depending on local timber supplies.

By transferring advanced technology to the private sector in this way, UNIDO is improving the competitiveness of small and medium enterprises and greening of supply chains.

UNIDO, in collaboration with the public sector, has granted the line of equipment for the production of bamboo laminated boards to CEO of the Dathri/Dowell Creations Display Systems, Tyrone Fernando on 25 November.

The machinery is to be used in his bamboo processing facility in Negombo. The launch event took place in Kadirana, Negombo, on November 25 in the presence of representatives of different UN Organizations and the public sector.

The two-day training of trainers for this production by IDB started on the same day.

This hands-on workshop provides opportunities to IDB trainers to gain the needed knowledge and experience on how to use and maintain the equipment properly, which they will disseminate at their facilities from next year.

Transferring this equipment is a step towards developing a national bamboo supply chain and product industry, and will make investments towards commercial bamboo plantations on degraded land economically attractive.

A second bamboo production machinery line will be imported and set up at the Industrial Development Board of Ceylon (IDB) in Moratuwa early next year, to support local capacities for technology promotion and transfer of necessary soft skills.

IDB is to establish a national bamboo training center and will promote the utilization of bamboo as a substitute for wood while tackling deforestation and creating innovative and sustainable products.